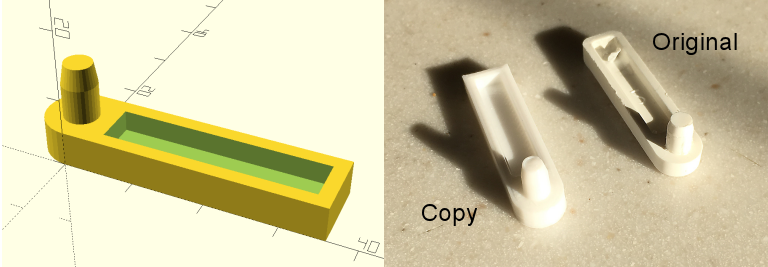

Way back when I bought my Billy bookcases, IKEA offered an extension that added a low cupboard to the base. The extension is no longer available. Plastic stoppers prevented the cupboard doors from swinging inward. At some point, over the years, I lost a stopper. Its replacement seemed an obvious choice for my first 3D printing design experiment.

OpenSCAD

After some false starts with Blender, I used OpenSCAD to create the .stl file. OpenSCAD uses a script in its language to create a model. With the help of boolean operators, the door stopper could be defined as the union or difference of a small number of primitive 3D objects.

|

1 2 3 4 5 6 7 8 9 10 11 12 13 |

difference() { union() { cube ([36,10,5]); translate ([0,5,0]){ cylinder (5,5,5,$fn=32); cylinder (10,2.5,2.5,$fn=32); translate ([0,0,10]) cylinder (3,2.5,2,$fn=32); } } translate ([5,2,2]) cube ([29,6,4]); } |

I did not copy the original precisely. It had a slight bevel to soften exposed edges that I did not reproduce. It also had a slight lip to fatten the end that met the door. Reproducing that would have required the introduction of supports and I did not want that complication.

Printing

Printing also had some false starts. The first print attempt failed on the first couple of layers. Perhaps the extruder temperature was not high enough (I used the default of 200 °C initially, increasing it to 210 °C subsequently) or perhaps there was a problem with the bed levelling (a small amount of extruded PLA on the tip of the nozzle may have thrown things off). For the successful print, I added a skirt.